Cold Storage Design Parameters and Guide to Selecting Cooling Fans

2025-04-06

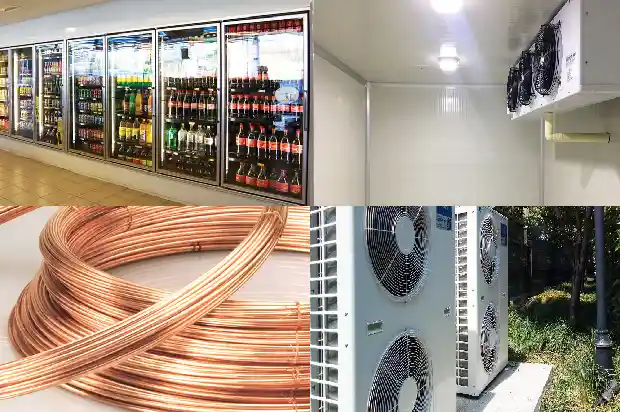

When designing a cold storage, some parameter issues need to be considered.

First, understand the following points:

- Know the location of the cold storage to be built, its size (length, width, height, storage capacity in tons, cubic meters, crates, boxes, etc.);

- Determine what commodities the cold storage will store. Specific requirements such as storage temperature, storage duration, and the time it takes to reach the set temperature can all be specified;

- If your cold storage is relatively large, understand the quantity of goods entering and leaving the warehouse, the temperature of the incoming and outgoing products, and the number of times the door is opened, etc.

;

- Once these are clear, it's time to choose materials, such as compressors, refrigeration units, air coolers/pipe coils, insulation materials, condensers, doors, temperature controls, and other refrigeration equipment.

- Air coolers/pipe coils: They come in different sizes and are for high and low temperatures. Pipe coils: There are aluminum coils, iron coils, etc., mostly used for low - temperature storage of meat products.

- Temperature control system: It adopts an advanced microcomputer control system and advanced control methods. The liquid crystal display shows the temperature inside the warehouse, startup time, defrosting time, fan delay time, and various technical parameters. It is simple to operate and very convenient for users.

How to choose an air cooler for a small cold storage II. Air coolers matched with freezer cold storage:

Calculate the load per cubic meter as W0 = 70W/m³.

Calculate the load per cubic meter as W0 = 70W/m³.

- If V (cold storage volume) < 30m³ and the cold storage has frequent door - opening times, such as a fresh meat cold storage, then multiply by coefficient A = 1.2;

- If 30m³ ≤ V < 100m³ and the cold storage has frequent door - opening times, such as a fresh meat cold storage, then multiply by coefficient A = 1.1;

- If V ≥ 100m³ and the cold storage has frequent door - opening times, such as a fresh meat cold storage, then multiply by coefficient A = 1.0;

- If it is a single freezer, then multiply by coefficient B = 1.1. Finally, the air cooler for the cold storage is selected according to W = A * B * W0 (W is the load of the air cooler).

- When the cold storage shares a refrigeration unit with a low - temperature cabinet, the unit and air cooler are matched according to an evaporation temperature of - 35°C. When the cold storage and the low - temperature cabinet are separated, the cold storage refrigeration unit and air cooler are matched according to an evaporation temperature of - 30°C.

Related Articles

- The Basic Refrigeration Working Principle of Cold Storage

- What Causes the Evaporation Temperature in a Cold Storage Refrigeration System to Be Too Low?

- Introduction to the Installation Process of Marine Prefabricated Cold Storage

- In - depth Explanation of Large - temperature - difference Ice - storage Air - conditioning Systems

- Is Three - phase Electricity Necessary for a Small - scale Cold Storage (Approximately 30 Cubic Meters)?

- Introduction to Cold Storage Refrigeration Systems

- Why should polyurethane cold - storage panels be selected for the construction of cold storages?

- Comprehensive Insights into Large - Temperature - Difference Ice - storage Air - Conditioning Systems

- How to Operate the Cold - storage Distribution Box during Cold - storage Installation

- Collection! Comprehensive Guide to Energy Saving of Refrigeration Systems - Cold Storage System Edition

- What Should Be Done When These Problems Occur in the Semi-hermetic Piston Compressor of the Cold Storage?

- Analysis of Common Malfunctions and Treatment Methods of Cold Storage Equipment

- What Are the Daily Maintenance Methods for Controlled Atmosphere Cold Storage Equipment?

- What are the Differences between Controlled Atmosphere Cold Storage Technology and Traditional Cold Storage Technology?

- Common Faults and Solutions in Cold Storage Maintenance

- Analysis of Classification, Differences, Advantages and Disadvantages of Cold Storage Refrigeration Compressors

- Liquid Supply Methods for Cold Storage Refrigeration Systems

- Is the Compressor in the Cold Storage Overheating in Summer? Find the Reasons Here!