The Circulation Principle of the Variable Refrigerant Flow (VRF) System and the Functions of Each Component Are Clearly Explained!

2025-04-12

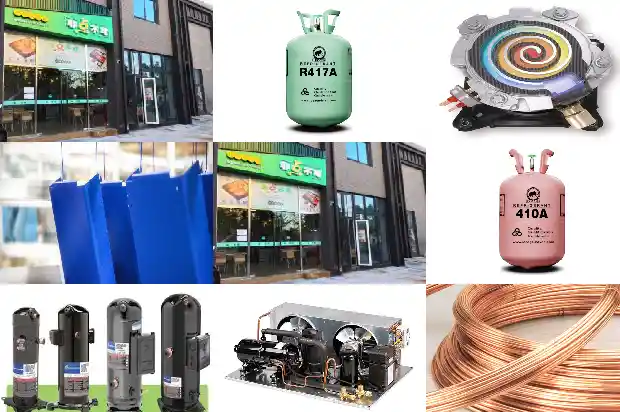

The variable refrigerant flow multi-connected air conditioning system, also known as the variable refrigerant flow (VRF) system, consists of one outdoor unit connected to several direct evaporative indoor units of different or the same type and capacity, forming a single refrigeration/heating cycle air conditioning system. It is also simply referred to as VRV or VRF.

Analysis of the Advantages and Disadvantages of the VRF System

Advantages

It saves building floor space, provides precise temperature control and high comfort;

It has a relatively low noise level and operates quietly;

It is more energy-efficient for small-area use, with lower operating costs, flexible control, and can be remotely controlled via telephone and modem;

It is convenient for construction and installation and can meet the requirements of different working conditions;

It saves building floor space, provides precise temperature control and high comfort;

It has a relatively low noise level and operates quietly;

It is more energy-efficient for small-area use, with lower operating costs, flexible control, and can be remotely controlled via telephone and modem;

It is convenient for construction and installation and can meet the requirements of different working conditions;

Disadvantages

The initial investment is relatively high;

If a fresh air system is required, it needs to be added separately;

There are strict limitations on the length of the refrigerant pipes and the height difference between the indoor and outdoor units;

It is not suitable for rooms with a large depth. The static pressure outside the unit is small, and the air supply distance is short;

The refrigeration (heating) capacity of a single unit is limited and cannot meet the air conditioning requirements of larger rooms;

The initial investment is relatively high;

If a fresh air system is required, it needs to be added separately;

There are strict limitations on the length of the refrigerant pipes and the height difference between the indoor and outdoor units;

It is not suitable for rooms with a large depth. The static pressure outside the unit is small, and the air supply distance is short;

The refrigeration (heating) capacity of a single unit is limited and cannot meet the air conditioning requirements of larger rooms;

The Refrigeration and Heating Cycle of the VRF System

Principle of the Refrigeration and Heating Cycle

The refrigerant is compressed by the compressor, and the originally low-temperature and low-pressure refrigerant gas is compressed into a high-temperature and high-pressure superheated vapor, which is then discharged from the exhaust port of the compressor. After the high-temperature and high-pressure gaseous refrigerant is discharged from the exhaust port of the compressor, it is sent into the condenser through the electromagnetic four-way valve. The high-temperature and high-pressure refrigerant gas enters the condenser, and the axial fan cools down the condenser. The refrigerant in the condenser pipes is cooled and then sends out a medium-temperature and high-pressure liquid refrigerant. After the medium-temperature and high-pressure liquid refrigerant is sent out from the condenser, it passes through the one-way valve, then through the drying filter, and then through the electronic expansion valve for throttling and pressure reduction, becoming a low-temperature and low-pressure refrigerant liquid, which is then sent into the pipes of the indoor units respectively.

The heating principle is basically the same as the refrigeration principle. The difference is that the valve block in the electromagnetic four-way valve is reversed through the control of the circuit system, thus changing the flow direction of the refrigerant and achieving the conversion from the refrigeration function to the heating function.

The refrigerant is compressed by the compressor, and the originally low-temperature and low-pressure refrigerant gas is compressed into a high-temperature and high-pressure superheated vapor, which is then discharged from the exhaust port of the compressor. After the high-temperature and high-pressure gaseous refrigerant is discharged from the exhaust port of the compressor, it is sent into the condenser through the electromagnetic four-way valve. The high-temperature and high-pressure refrigerant gas enters the condenser, and the axial fan cools down the condenser. The refrigerant in the condenser pipes is cooled and then sends out a medium-temperature and high-pressure liquid refrigerant. After the medium-temperature and high-pressure liquid refrigerant is sent out from the condenser, it passes through the one-way valve, then through the drying filter, and then through the electronic expansion valve for throttling and pressure reduction, becoming a low-temperature and low-pressure refrigerant liquid, which is then sent into the pipes of the indoor units respectively.

The heating principle is basically the same as the refrigeration principle. The difference is that the valve block in the electromagnetic four-way valve is reversed through the control of the circuit system, thus changing the flow direction of the refrigerant and achieving the conversion from the refrigeration function to the heating function.

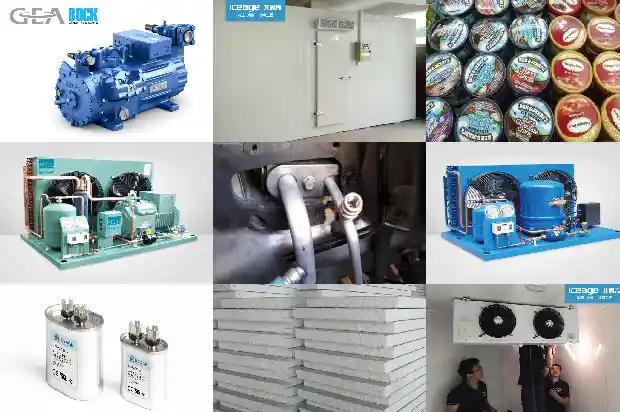

Analysis of Each Component of the VRF System

- Compressor: The heart of the refrigeration system. It sucks in low-temperature and low-pressure gaseous refrigerant and discharges high-temperature and high-pressure gaseous refrigerant. The compressor is the power source of the refrigeration system.

- Compressor heating belt: It raises the temperature of the compressor, volatilizes the liquid refrigerant inside into a gas, and prevents liquid slugging from damaging the compressor. Generally, this heating belt really comes into play when it is powered on for the first time after installation or when the unit is not turned on for a long time in winter.

- Compressor exhaust temperature sensing bulb: It detects the exhaust temperature of the compressor and prevents the exhaust temperature of the compressor from exceeding the set temperature, so as to control and protect the compressor.

- High-pressure switch: When the exhaust pressure of the compressor exceeds the action value of the high-pressure switch, it immediately sends a feedback signal to stop the operation of the whole unit, achieving the purpose of protecting the compressor.

- Oil separator: It separates the lubricating oil in the high-pressure steam discharged by the refrigeration compressor. At this time, the refrigerant and oil in the separation system rely on the oil separator to prevent a large amount of refrigeration oil from entering the refrigeration system and the compressor from lacking oil. At the same time, through separation, the heat transfer effect in the condenser and the evaporator is improved.

- Oil equalizer: The function of the oil equalizer is to "balance the oil level between different parts of the air conditioning system" to prevent partial lack of oil.

- One-way valve: In the refrigeration system, it prevents the reverse flow of the refrigerant, prevents high-pressure gas from entering the compressor in the wrong direction, and quickly balances the suction and exhaust pressure of the compressor.

- High-pressure sensor: It detects the real-time high-pressure value of the refrigeration system. If the high-pressure value exceeds the set value, it sends a feedback signal to protect the compressor and perform other controls.

- Four-way valve: The four-way valve consists of three parts: the pilot valve, the main valve, and the electromagnetic coil. By turning the current of the electromagnetic coil on and off, the left or right valve plug is opened or closed, so that the pressure on both sides of the valve body can be controlled by the left and right capillary tubes. The sliding block in the valve body slides left and right under the action of the pressure difference, thus changing the flow direction of the refrigerant to achieve the purpose of refrigeration or heating.

- Condenser: The condenser cools the high-temperature and high-pressure refrigerant steam discharged by the compressor. The high-temperature and high-pressure refrigerant gas condenses here and exchanges heat with the air through forced convection.

- Fan: Its main function is to strengthen the convective heat transfer, improve the heat transfer effect. It absorbs heat and dissipates cold during refrigeration and absorbs cold and dissipates heat during heating.

- Defrosting temperature sensing bulb: It controls the reset temperature of defrosting. When the set temperature of the sensing bulb is reached, the defrosting stops. It is used for defrosting detection and control.

- Electronic expansion valve: The function of the electronic expansion valve is throttling. The main difference between it and the capillary thermal expansion valve is that it controls the opening degree through a controller and can adjust the opening degree of the valve port as needed, thus controlling the flow rate. Using an electronic expansion valve can make the flow rate adjustment more accurate, but the price is relatively much higher.

- One-way valve: It prevents the reverse flow of the refrigerant in the refrigeration system.

- Subcooler electronic expansion valve: When the system is operating for refrigeration, it controls the subcooling degree of the refrigerant in the liquid pipe, reduces the energy loss of the pipeline, and increases the refrigeration capacity of the refrigeration system.

- Subcooler liquid outlet temperature sensing bulb: It detects the temperature of the liquid pipe and sends it to the control panel to adjust the opening degree of the electronic expansion valve.

- Gas-liquid separator inlet pipe temperature sensing bulb: It detects the temperature of the inlet pipe of the gas-liquid separator to avoid the compressor running with liquid return.

- Subcooler outlet temperature sensing bulb: It detects the temperature of the gas side of the subcooler, inputs it to the control panel, and adjusts the opening degree of the expansion valve.

- Gas-liquid separator outlet pipe temperature sensing bulb: It detects the internal state of the gas-liquid separator and further controls the suction state of the compressor.

- Ambient temperature sensing bulb: It detects the ambient temperature in which the outdoor unit operates.

- Low-pressure sensor: It detects the low-pressure value of the refrigeration system. If the low pressure is too low, it sends a feedback signal to avoid operating at too low a pressure, which may cause compressor failures.

- Gas-liquid separator: The main function of the gas-liquid separator is to store part of the refrigerant in the system, preventing the compressor from liquid slugging and the excessive refrigerant from diluting the compressor oil.

- Unloading valve: The main function of the unloading valve is to automatically control unloading or loading to avoid dead zones in the pipeline, resulting in excessive pressure.

Related Articles

- Refrigeration System Circulation and Components for Freezing and Cold Storage

- Principles, Characteristics, Selection and Precautions of Air-cooled Modular Units

- The Basic Refrigeration Working Principle of Cold Storage

- Eye - opening! Dynamic Demonstration of the Principles and Applications of Refrigeration Systems

- Classification, Principle, Model Selection and Application, and Troubleshooting of Fan Coils

- Working Principle and Characteristics of Screw Compressors

- HVAC - Concise Explanation of Refrigeration Principles

- Working Principle and Daily Maintenance of Water-based Machines

- Analysis of the Working Process and Principle of Hot Fluoride Defrosting for Air Coolers

- Principles and Applications of Common Pressure Control and Pressure Regulating Valves

- Screw Compressor Units: Principles, Design and Selection - Essential Guide for Refrigeration Beginners

- Principles, Components and Heat Recovery of Modular Units

- What are Refrigeration Equipment? What's the Principle of Chillers?

- What Is the Working Principle of Refrigeration Equipment?

- Operating Principle and Standard Installation Steps of Multi - split Systems in Refrigerant Air - conditioning Systems

- Working Principle of AC Inverter and DC Inverter Air Conditioners

- What's the principle and function of air energy?

- Principles of Refrigeration Systems and Functions of Components Explained